Frequently Asked Questions

OUR LATEST PRODUCT LAUNCH

Photovoltaic modules for indoor IoT. Recycling ambient light; converting it to electricity

PVModules FAQ

01

WHO ARE THE TYPICAL CUSTOMERS FOR PVMODULES?

02

WHAT ARE THE TYPICAL DEVICES THAT CAN BENEFIT FROM PVMODULES?

03

WHAT ARE THE SPECIFICATIONS OF YOUR PVMODULES?

04

DO YOU SELL SOLAR MODULES/PANELS?

05

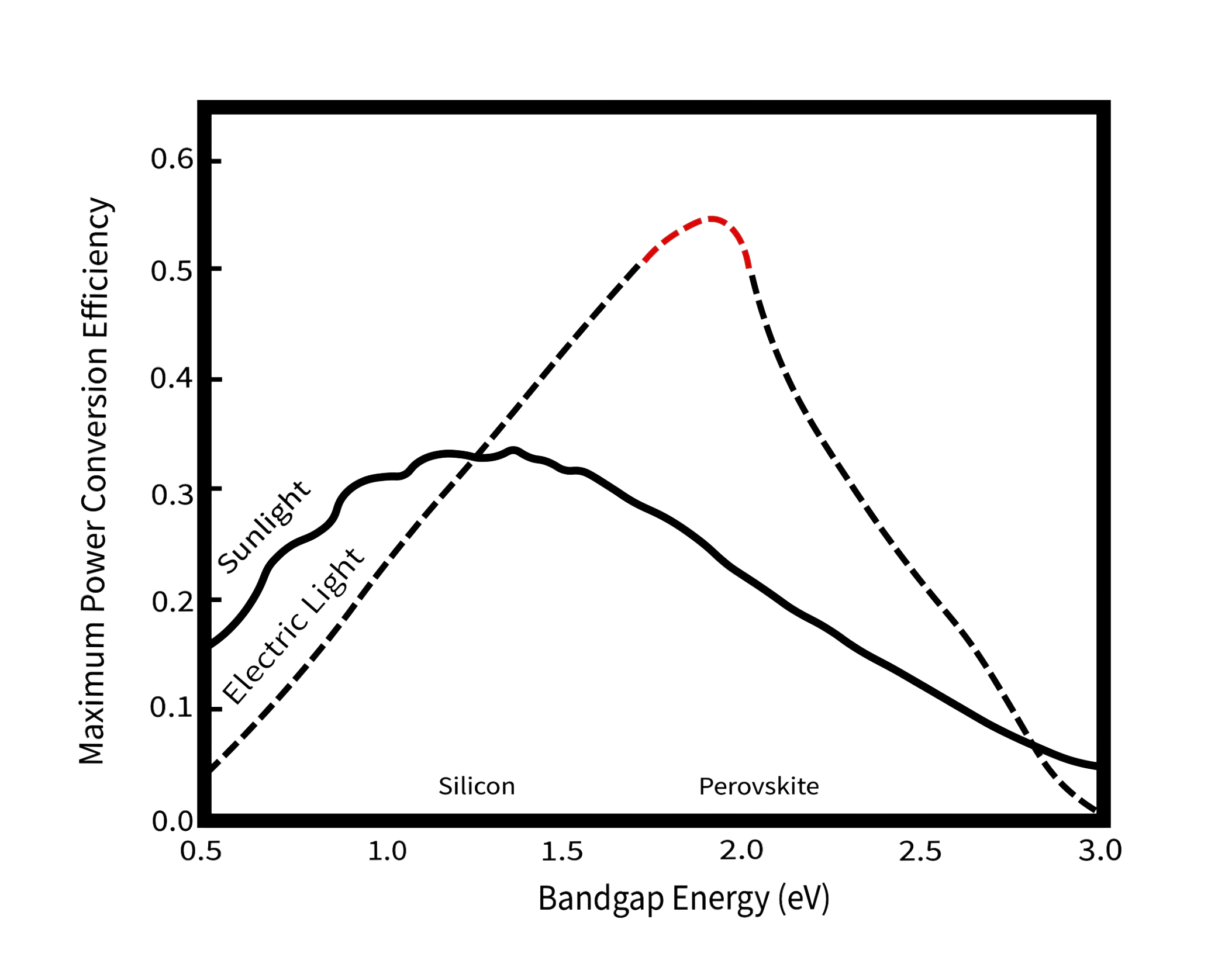

WHY USE PEROVSKITE PHOTOVOLTAICS FOR INDOOR APPLICATIONS?

06

HOW IS INDOOR AND OUTDOOR LIGHT DIFFERENT?

07

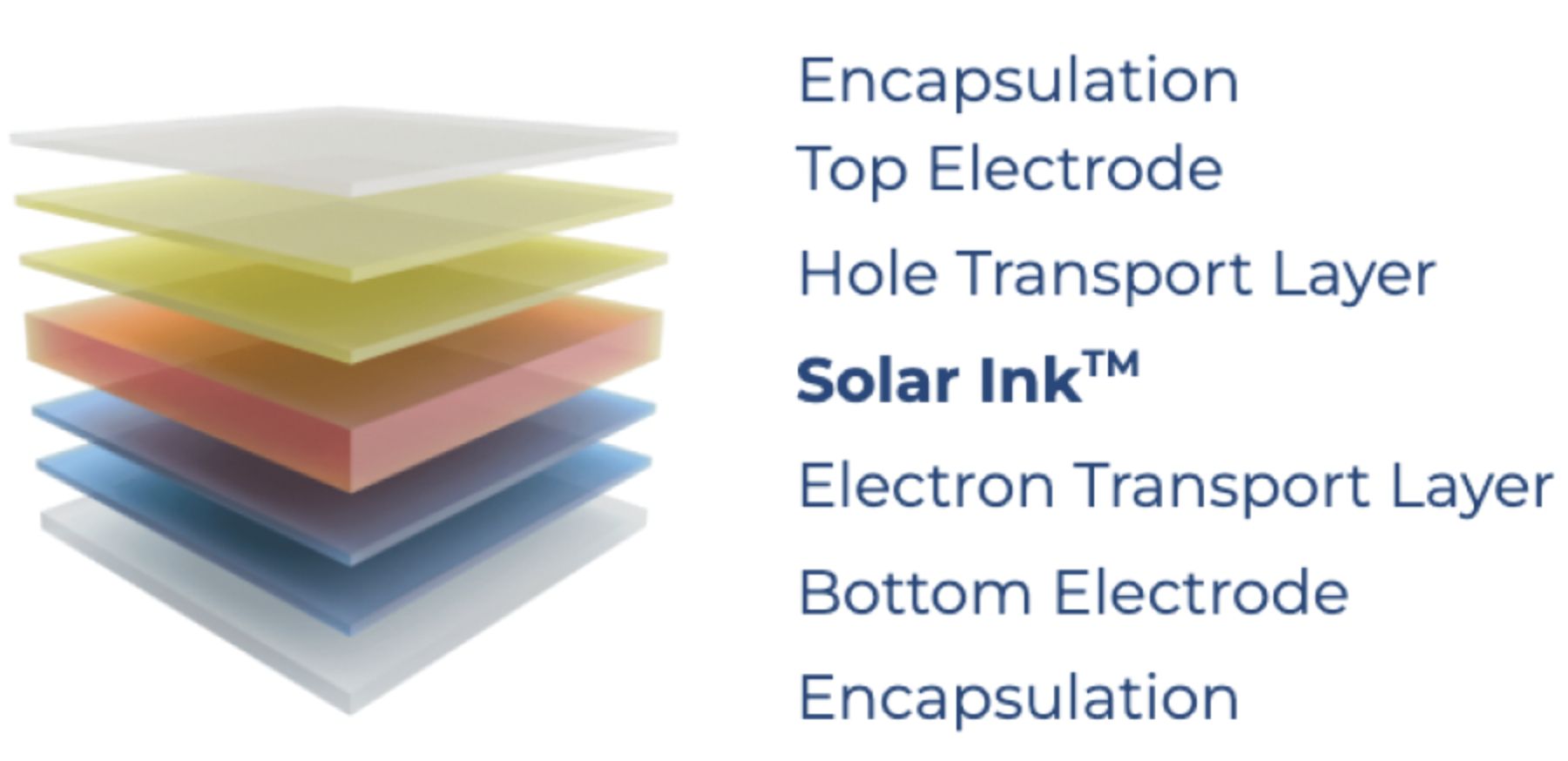

ARE PVMODULES MANUFACTURED WITH SOLAR INK?

08

WHERE ARE PVMODULES MANUFACTURED?

PVModules FAQ

01

CAN I COAT ANY SURFACE WITH SOLAR INK TO MAKE IT A SOLAR CELL?

02

WHO ARE THE TYPICAL CUSTOMERS FOR SOLAR INK?

03

IS SOLAR INK COMPATIBLE WITH A SPECIFIC COATING METHOD?

04

WHAT IS THE DIFFERENCE BETWEEN SOLAR INK ONE AND SOLAR INK EVOLVED?

05

WHAT IS THE DIFFERENCE BETWEEN SHELF TIME AND LIFETIME?