The Importance of Green Perovskite Inks

Solaires Team | Victoria, B.C. | March 2023

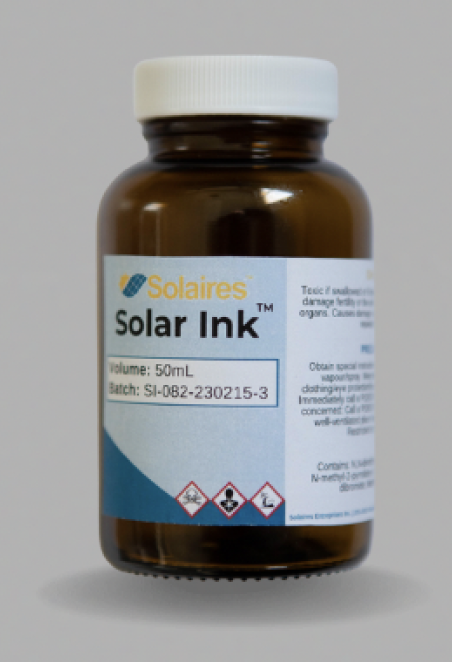

At Solaires, we have an overarching motto to guide all of our products: photovoltaic solutions for a cleaner world. As we’ve discussed before, our perovskite solutions are simply cleaner than the dominant silicon technologies. However, along with the rest of the chemical industry, we must innovate to provide the cleanest and greenest solutions possible. As we launch our second Solar Ink™ product, we specifically looked at “greening” the solvents included in our products.

As with many fields, “green” chemistry has been used broadly to describe a wide range of harm reduction strategies. “Greening” solvent choices often refers to four broad categories:

![]() Environmental Impact

Environmental Impact

![]() Regulations

Regulations

![]() Worker Health and Safety

Worker Health and Safety

![]() Sustainability

Sustainability

Of course, any of the benefits of green solvents must be paired with cost-effective and high quality products, or else they would never be adopted in the marketplace, if not for strong regulatory incentives.

The vast majority of commercial solvents come from oil precursors. While the source itself is unsustainable, the energy cost of manufacture and isolation of solvents must also be taken into account, and their CO2-equivalent cost in terms of GHG emissions are carried forward into products which use them.

On an industrial and commercial scale, solvent use and waste is heavily regulated. Companies like ours cannot simply pour our waste solvent down the drain. Not only is that against local and federal regulations, but it is morally unconscionable to introduce that waste into the environment. So, a large portion of our internal solvent cost comes from waste recycling and removal. When possible, it would be ideal if we could recycle our solvent waste with low-energy isolation methods, though many solvents are unsuitable for such re-use. Solvents which cannot be recycled are often incinerated, releasing CO2 and other burdens into the environment. Environmental impacts include more than just energy costs. Environmental release of solvents is a major problem which labs must limit as much as possible, though occasionally release is impossible to avoid. Whether in the atmosphere or into water reservoirs, solvents can have a major detrimental impact on the environment.

As far as health impacts of solvents, a few household products (like paint thinners and degreaser) transfer health impacts to end-users. This is not the case for perovskite solar cell (PSC) manufacturers. The end products, solar modules, do not contain solvents. Instead, the manufacturing process of PSCs includes several compounds which are dissolved in potentially harmful solvents, before the solvents are removed as a solar cell is manufactured. The health and safety risk of solvents used at Solaires comes from our employees and the employees of our Solar Ink™ customers. Environmental impact and worker health and safety concerns are often merged together to outline an overall environmental health and safety (EHS) profile. Major pharmaceutical companies are widely respected leaders in the solvent selection field. For both internal and external purposes, these companies release solvent selection guidelines which represent a reliable target to strive for our own products. Those guidelines are listed in three categories: preferred, usable, and undesirable.

Solvents like NMP and DMF are compatible with research and development purposes. In these cases, the focus of using perovskite inks is to study and adjust other pieces of the solar cell puzzle, like cell architecture, encapsulation studies, or elucidating ageing pathways. However, when it comes to scaling up to mass manufacture of PSCs, DMF and NMP have to be replaced. Using pharmaceutical company’s guidelines as our bearing, both DMF and NMP are listed as “undesirable”. Additionally, we can cross-compare with USEtox, the UN endorsed tool for characterising human toxicity and freshwater ecotoxicity of chemical usage.

These EHS concerns have led Solaires to the development of our second Solar Ink™ product, Solar Ink™ Evolved. By ditching both NMP and DMF in our solvent system, we are able to provide our safest formulation yet. We replaced the “undesirable” solvents with GBL, propanol, and acetic acid. As a small alcohol molecule, propanol is listed as “preferred” by pharma, while acetic acid is described as “usable”. Where pharma do not have specific recommendations for GBL, we can point to USEtox. USEtox lists DMF as the most dangerous, about 8 times more toxic than both NMP and GBL, while NMP and GBL have somewhat comparable toxicities.

We are excited to announce the availability of Solar Ink™ Evolved with a greener and safer solvent system. Adding to our excitement, the new solvent system was developed as our first product compatible with inkjet printers, opening the door to even more scalable coating and printing methods. We are proud innovators at Solaires, and are eager to open up the market for inkjet compatible perovskite inks. Solar Ink™ Evolved is a major boost to the scalable production of next-generation solar power.

Do you want to learn more about photovoltaic technology and its opportunities?