WHAT IS PEROVSKITE?

MAKE THE SWITCH TO PEROVSKITE PHOTOVOLTAICS

Solaires Team | Victoria, B.C. | APRIL 2021

To convert the sun's energy into usable electricity, all photovoltaic solar cells rely on semiconductors. Light from the sun excites electrons in the semiconductor, causing them to flow into conducting electrodes and generate an electric current. Since the 1950s, silicon has been the primary semiconductor material used in solar cells.

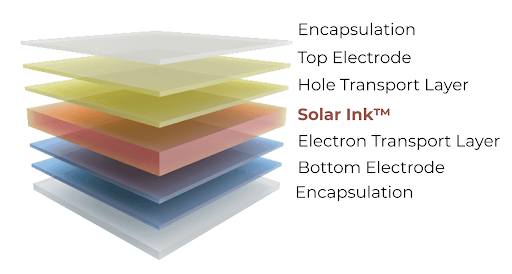

Now, perovskite materials have emerged as the most promising, efficient, and affordable semiconductor material for photovoltaic applications. Perovskite is a general term for a crystalline structure, including many lab-designed compositions which can act as the light harvesters of solar cells, replacing silicon. At Solaires, a specific formula of precursor chemicals are combined in a liquid solution to form our Solar InkTM. This ink is then deposited, and crystallised, onto a substrate and sandwiched between different layers including electrodes which make up a single solar cell in a solar panel, as seen here:

Perovskite can address some of the issues faced by silicon solar cells:

-

LESS WASTE. Perovskite solar modules are a few mm thick, compared to silicon solar panels which are tens of mm thick. The reduction of material required to make solar modules will reduce the waste generated.

-

HIGHER EFFICIENCY. Perovskite solar cells were first demonstrated in 2009, and were only able to convert 3.8 percent of incoming solar energy into electricity. In merely the last 12 years, perovskite solar cells are now able to harvest more than 25 percent of solar energy, about the same efficiency as silicon solar cells have topped out at for three decades! The growing perovskite field, with novel and innovative technologies, are soon expected to jump well past the maximum theoretical efficiency (~30 %) of traditional silicon cells.

-

EASE OF FABRICATION. Compared to silicon, solar panels made with perovskite require much less manufacturing energy and raw materials in their fabrication process. The fabrication of perovskite solar cells is relatively simple, meaning they could easily be fabricated all over the world. Only the purest of pure metallic silicon can be used to make solar panels, while perovskite precursors are easier to acquire.

-

MORE APPLICABILITY. Since perovskite solar cells are thinner than silicon solar cells, they can be produced as flexible and semi-transparent materials, which opens up many applications. Imagine solar panels so thin and flexible that they can take the shape of whatever surface they are on, without adding much weight. These panels could easily adopt the curves of a car or replace windows to create electricity, while still letting unabsorbed light in!

Perovskite offers new photovoltaic technologies with the potential to be more efficient, less polluting, and more adaptive than traditional silicon solar technology.

Interested in switching to perovskite PV technology?

Solaires is one of the few organisations in the solar industry directly involved in the development of the perovskite value chain. We are developing a perovskite-based solar ink and a perovskite solar cell manufacturing process that will transform the next generation of solar cells.

Get connected with our sales team today at

sales@solaires.net

!